pipe extruder manufactruer

Pipe extrusion line and accessories to increase production capacity

Plastic Machinery pipe extrusion lines are used for the production of rigid or flexible, single-layer or multi-layer, smooth, corrugated or gimped tubes with a different type of diameter.

PM offers:

- Extrusion line personalization consultancies

- Top quality and high production capacity

- Around the clock after-sale assistance

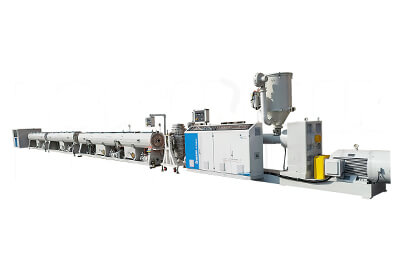

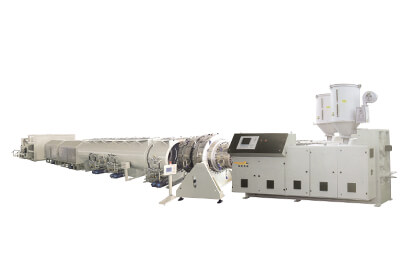

Plastic pipe extrusion lines

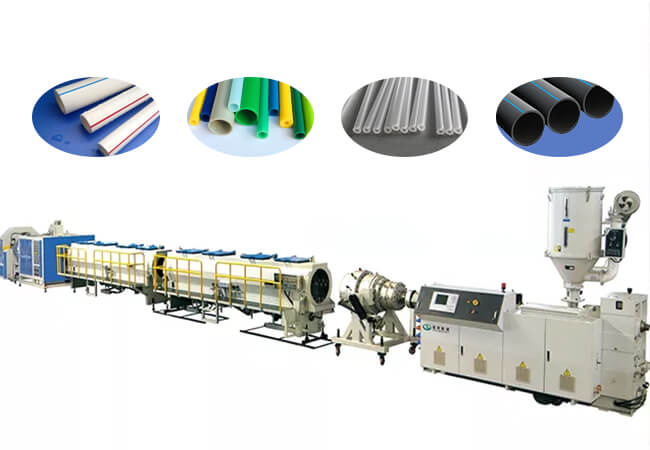

Our extruders work with R-PVC, U-PVC, P-PVC, PP, PE (Polyethylene) PC, HDPE, LDPE, TPU and WPC.

PE Pipe Extrusion Line

Our PE pipe extrusion line can produce PE size range from Ø16 to Ø2000mm for different kinds of PO materials: PP, PPR, PERT, PB, PEX-B, etc.

PVC Pipe Extrusion Line

Our PVC pipe extrusion line can produce PVC pipe size range from Ø16 to Ø1000mm for different kinds of PVC pipes: UPVC pipe, CPVC pipe, PVC-O pipe, PVC-M pipe, etc.

PP-R/PE-RT Pipe Extrusion Line

Our PPR pipe extrusion machine can produce PP-R size range from Ø16 to Ø160mm. Adding additional extruder and changing die head structure can produce PPR fiberglass composite pipe.

Corrugated Pipe Extrusion Line

Corrugated pipe extrusion line is used to produce corrugated HDPE, PVC and PVC pipes

Hollow Wall Winding Pipe Extrusion Line

HDPE Hollow Wall Spiral Pipe Extrusion machine is used to produce HDPE hollow wall pipes

PE/PP/PVC Single Wall Corrugated Pipe Making Machine PVC Braided Hose Extrusion Line

PP pipe extrusion line is used to produce OD16-800mm PP pipe ppr pipe extruding line

Production capacity from 50kg/hr to 700kg/hr for single extruder, 110-600kg/hr for conical twin screw extruder.

Simens motor, ABB inventer, OMRON temperature controller, JT GEARBOX, famous brand screw and barrel.

Our engineer will supply free formula details after buying our machines.

Our engineer will go to your factory to help you install machine and train your staffs if you need.

Professional Manufacturer for pipe extrusion line

Our complete solution including different kinds of plastic pipe machine to produce water supply pipe, gas supply pipe, drainage pipe, conduit pipe and other auxiliary machinery.

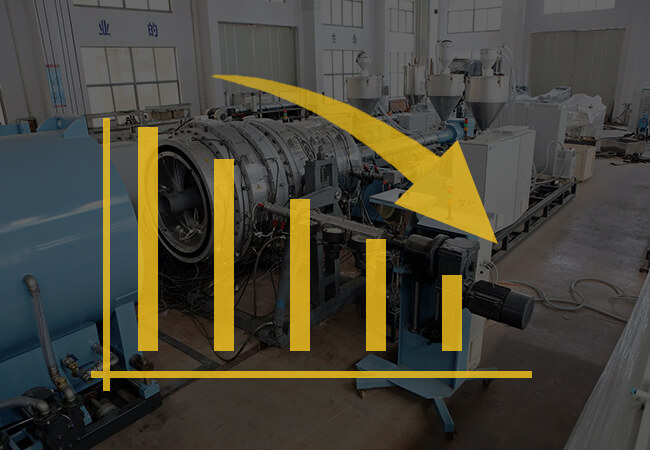

Save Energy

Advantages of profile extrusion

This unique combination, in a MEAF pipe extrusion line, gives you the following advantages compared to our competitors:

- Improved output by 20 – 100%;

- Reduce total energy consumption by 10 – 65%;

- Improved process stability at lower RPM’s (< 250 RPM’s);

- Universal suitability for nearly all thermoplastic resins., incl biodegradable variants;

- Problem free processing of regrind/recycled material up to 100%.

Range of Products

PM pipe extrusion lines produce tubes which are used in construction, agriculture, industry and many other sectors.

What do you need to produce?

We gather data, analyse requests and take note of the needs and objectives of the customer both in the short and long term.

Materials

Designed to meet a number of different needs, the Bausano extrusion lines for tubes are able to process several types of plastic materials:

- Soft and rigid, transparent, supercharged PVC, or combined with acrylic resins

- CPVC (Chlorinated polyvinyl chloride)

- PO, Polyolefins such as PE (Polyethylene), PP (Polypropylene), HDPE, LDPE

- PVC- or Polyolefin-based WPC

Applications

Thanks to their resistance and reliability, tubes produced with our tube extrusion lines are used in many industries and for a number of different applications:

- CONSTRUCTION: tubes for transport of liquids, for high pressure or for drainage

- CONDUITS: smooth corrugated or spiral tubes

- AGRICULTURE: tubes for irrigation, drip irrigation, braided tubes

- PETROCHEMICAL: transport of gases and hydrocarbons;

- MEDICAL: small tubes for medicinal products, pump pipes, dental tubes

- AUTOMOTIVE: air conveyance tubes and cable pipelines;

- TELECOMMUNICATIONS: cable protection tubes

FAQs

The pipe extruder machine, is the most important part of any pipe production line; it heats, mixes, and extrudes fesh pipe. A good extruder will ensure that you consistently produce quality pipe, allowing you to save money on scraped pipe and differentiate yourself from the competition.

The plastic pipe production line is composed of control system, extruder, head, setting cooling system, tractor, planetary cutting device and turnover frame.

Each pipe production line has two extruders. One extruder mainly adopts strong conveying bushing and high-efficiency screw, and the other smaller extruder is used to extrude the marking line.

Vacuum feeding—–hot melt extrusion—–vacuum sizing—–secondary spraying—–printing traction—–product cutting—–visual view Detection-package and store

PVC pipe production line is mainly used to produce PVC pipes, which are widely used in agricultural water supply and drainage, building water supply and drainage, cable laying and other aspects, as well as plastic PVC pipes with various pipe diameters and wall thicknesses. Because of its characteristics, CPVC plastic pipe is widely used in oil field crude oil gathering and transportation, chemical temperature and corrosion resistant pipeline, hot water and warm water supply and drainage pipeline, directly buried high-pressure and ultra-high-voltage power transmission, cable protection pipe and other fields.

PM offers both single screw extruders for plain PE and drip irrigation pipe as well as twin screw extruders for PVC pipe production. Our plastic pipe extruders are custom built to your needs and constructed from industry leading, brand name components.

PVC extruders require twin screws to handle the extra wear and tear caused by the rough nature of raw PVC materials. Unfortunately, using PVC resin with a single screw extruder will cause accelerated damage to the extruder and inconsistent pipe production.

The success over the years of plastic pipes is due to their characteristics. Plastic pipes are light in weight, tough, resistant to chemical attack and available in large lengths. Also, plastic pipes are not suggested to rust and have good elastic properties.

For this reason Pipe production and Pipe extrusion have seen a growing demand in the last years. Also, the demand of new type of plastic materials has grown due to optimized cost and quality.

Contact our support team

If you have any questions, please contact us in time!

You will get feedback within 24 hours.